Vacuum and Nitrogen Flashing Can Seaming Machine for Baby Formula

Product Description

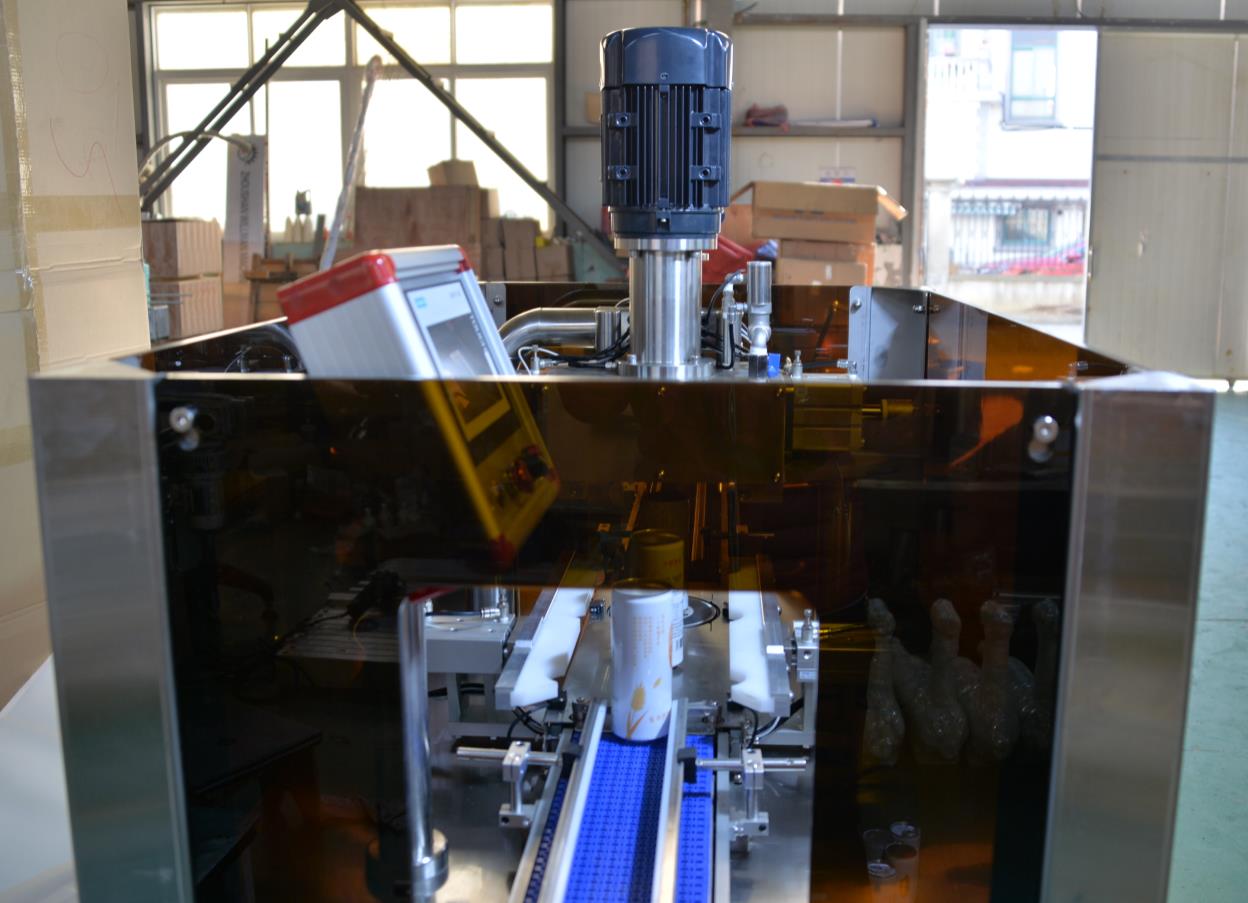

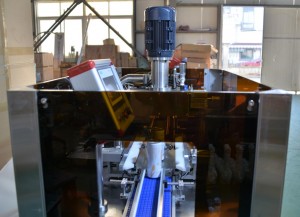

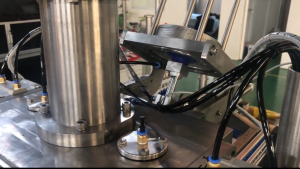

This machine is a new type of can sealing machine designed for the packaging industry of milk powder, protein powder and other high-end products. It is kind of sealing machine suitable for sealing all kinds of tinplate cans, aluminum cans and other round cans. This machine integrate the function of vacuum, liquid nitrogen dosing and sealing in one machine unit. This machine adopts electrical integrated control, human interface, automatic lid feeding, automatic in and out of the can, automatic vacuum and nitrogen dosing, and oil-free automatic sealing. The working parameters can be easily set on human interface according to different size of round cans. The main electrical components all adopt imported vitality parts.

Technical Parameters

Double Head Automatic Vacuum Nitrogen Seaming Machine For Metal Can

|

No. |

Item |

Unit |

Paramaters for 1 head |

Paramaters for 2 heads |

|

|

1 |

Capacity | LN2 Dosing Mode |

can/min |

6~7 |

12-14 |

| Normal Mode |

can/min |

10 |

20 |

||

|

2 |

Residual amount of oxygen |

% |

<3% |

<3% |

|

|

3 |

Seaming Head |

head |

1 |

2 |

|

|

4 |

ApplicableCan Size | Can Height |

mm |

D73~D126.5 (300~502) |

D73~D 126.5 (300~502) |

| Can Diameter |

mm |

100-190 |

100-190 |

||

|

5 |

Compressed air consumption |

m3/min |

0.3 |

0.5 |

|

|

6 |

Compressed air requirements |

|

0.6~0.8MPa; D8 air pipe |

0.6~0.8MPa; D10 air pipe |

|

|

7 |

Nitrogen consumption |

L/can |

15 |

30 |

|

|

8 |

Nitrogen Requirements |

|

0.2~0.4MPa |

0.4~0.8MPa |

|

|

8 |

Main Power |

Kw |

4(Including vacuum pump) |

3.5+5.5 (Including vacuum pump) |

|

|

9 |

Votage |

|

3 Phase 380V/50HZ |

3 Phase 380V/50HZ |

|

|

10 |

Weight |

kg |

700 |

900 |

|

|

11 |

Dimension |

mm |

1900×850×1700 |

2060×1050×1700 |

|

Performance and Characteristics

(1)The appearance and main parts of the machine are made of 304 stainless steel;

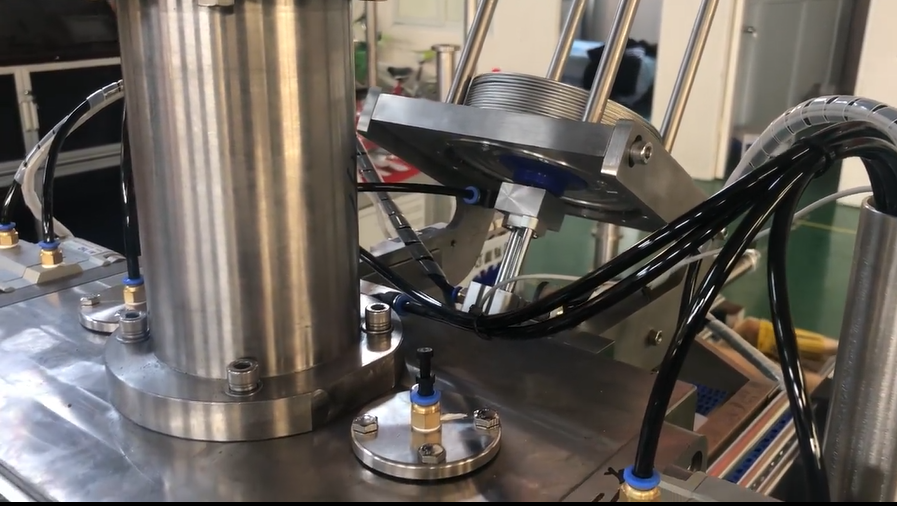

(2)The seal of the vacuum system adopts vacuum special fluorine rubber seal ring, which is resistant to high temperature and leak-proof

(3)Human-machine interface operation, PLC control system, simple operation

(4)Xinje touch screen, Siemens programmable controller

(5)Omron position detection photoelectric

(6)Pneumatic actuators, solenoid valves, and cylinder position detection sensors all adopt Airtac brand

(7)Vacuum pump adopts well-known domestic vacuum pump

(8) Reach Double seaming structure standard, in good sealing quality

(9)The roller adopts the latest materials and heat treatment methods, the service life is greatly improved, the curling edge is smooth and uniform, no scratches, and the sealing quality is improved.

(10)According to the requirements of sealing quality and residual oxygen, it can be easily changed and set on the man-machine interface

(11)The use of oil-free and maintenance-free bearings makes the equipment cleaner and ensures a clean working environment in the production workshop;

(12)All actuators are driven by cylinders and motors, which makes oil pollution working situation

(13)The man-machine interface provides fault alarm functions such as no cover, lack of cover, blocked tank, non-drop tank, servo, cylinder, etc., making the fault clear at a glance, greatly shortening the troubleshooting time and improving production efficiency;

(14)Equipped with automatic timing vacuum function to prevent dust accumulation inside the vacuum hood.

(15)Especially in the vacuuming and nitrogen filling method, it can effectively prevent the dust from flying again.

Electrical Configuration

|

No. |

Item |

Qty' |

Brand |

|

1 |

Motor |

1 |

SMS |

|

2 |

Photoelectric switch |

3 |

Omron |

|

3 |

S7-200 |

1 |

Siemens |

|

4 |

Expansion module |

1 |

Siemens |

|

5 |

Expansion module |

1 |

Siemens |

|

6 |

Touch screen |

1 |

XINJE |

|

7 |

Inverter |

1 |

Delta |

|

8 |

Inverter |

1 |

Delta |

|

9 |

Switching power supply |

1 |

Mingwei |

|

10 |

Vacuum sensor |

1 |

Delta |

|

11 |

Vacuum pump |

1 |

|

|

12 |

Conveyor motor |

2 |

JSCC |

|

13 |

The electromagnetic valve |

15 |

AirTAC |

|

14 |

Cylinder |

11 |

AirTAC |