Chinese wholesale Automatic Canned Beans Canning Line Beans Canning Production Line Machinery

We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation for Chinese wholesale Automatic Canned Beans Canning Line Beans Canning Production Line Machinery, We sincerely welcome consumers from both at home and overseas to come to negotiate company with us.

We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation for China Canned Food Machinery and Canning Machinery, We are going to initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our products or would like to discuss a custom order, make sure you feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future.

Canned Sweet Corn Production Line Description

Willman Machinery- professional canned food and beverage machinery manufacturer from China.

Our factory is specialized in canned food machinery production, supplying whole production line for customers. Based on our rich experience in the field of food machinery, we have been providing our customers whole production line like canned sweet corn production line, canned pineapple in syrup production line, canned beans production, canned peas production line ,canned mushroom production line ect, and we have got good reputation.

By analysis your factory location as well as your actual usage, we anticipate possible problems and solve them one by one, we are aim to provide you best production line design.

Canned sweet corn production line absorbs advanced technology and combine with the actual situation of the domestic and developed technology overseas, it has became one main and rich experienced product line of our products.

4 to 5 tons / hour, 6 to 8 tons / hour , 8 to 10 tons/hour capacity is the normal production line.

Design whole production line layout according to your factory actual usage .

Committed to provide reasonable design, energy saving and stable machine to keep stable capacity for customers.

The main process of canned sweet corn

1. Sweet corn raw materials: Sweet corn raw materials are required to be ripe and tender, with golden to light yellow grains, thin skins, high sugar content, and good color and fragrance.

The raw materials are processed quickly after entering the factory. The raw materials harvested on the same day are required to be processed on the same day.

2. Remove the corn peel and ears: remove the peel and ears, wash them in water, and use a brush to remove the remaining ears and whiskers, and remove the unqualified corn such as old and moth-eaten.

3. Sweet Threshing: pay attention to keeping the grains neat and tidy, prevent the core from being cut off, select the grains, remove the whiskers, cores and other impurities, and heat immediately.

4. Pre-cooking and cooling: 85-90 degrees Celsius water

5. Weighing and canning

6. Soup preparation: set 425g canned sweet corn as example

|

Can Size |

N.w.(g) |

D.w.(g) |

F.w. (g) |

|

7113# |

425 |

270 |

270~275 |

100kg water; 1.2kg refined salt; 7kg white granulated sugar (adjust in time according to the sugar content of the variety.)

7. Sealing: The temperature of the center of the tank shall not be lower than 85℃ during sealing.

8. Sterilization and cooling

9. Instructions and precautions

A. The empty cans are tinplate cans with anti-sulfur paint.

B. The color, aroma, and taste of sweet corn are not only related to the variety of raw materials, but also closely related to the maturity and freshness of the harvest. It must be processed in time after harvest in the milk-ripe period, and the processing flow must be rapid.

If necessary, the raw materials can be harvested twice a day.

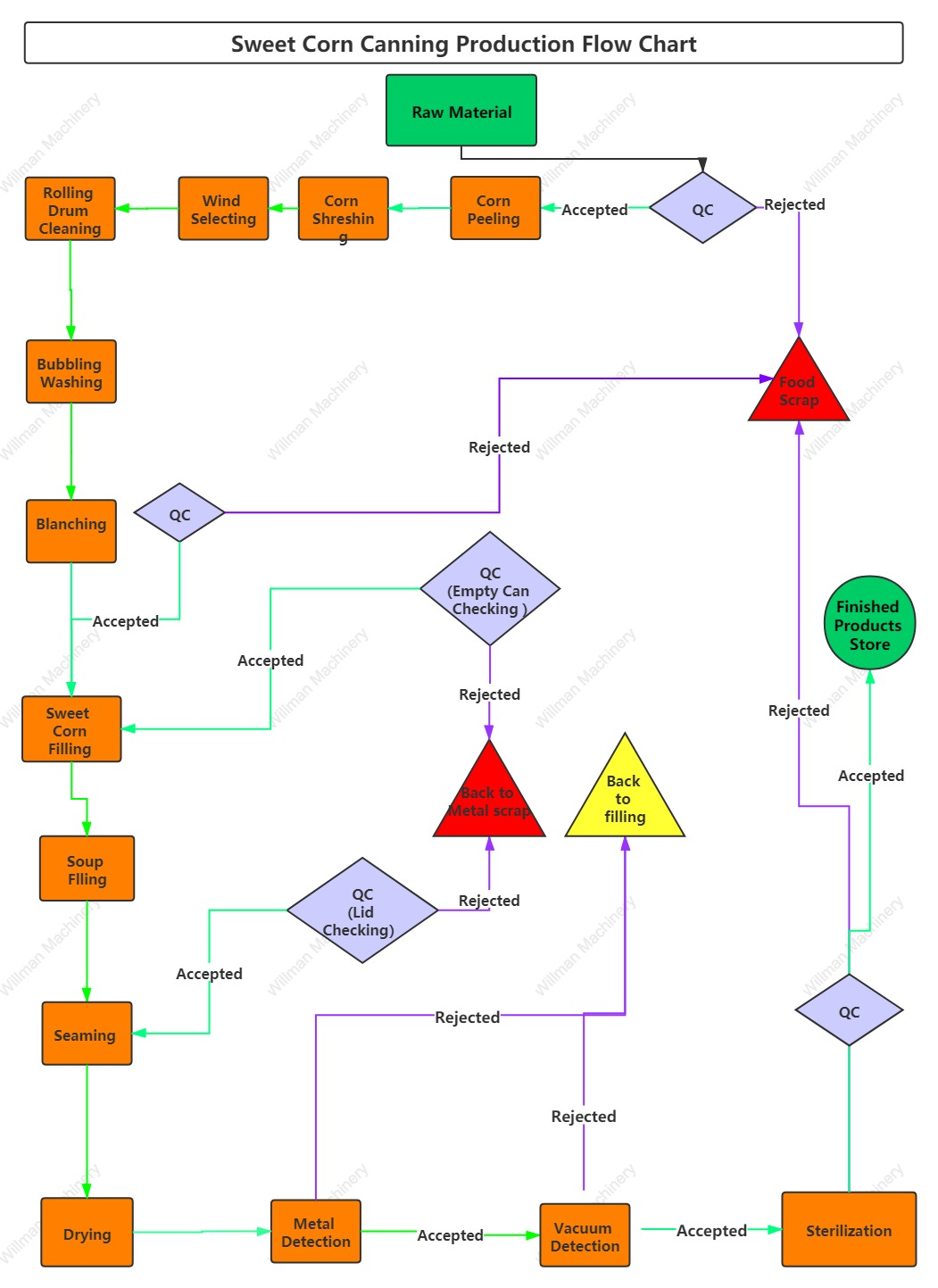

Canned sweet corn production line flow chart

This canned sweet corn production line flow chart is made according to one big company who product canned sweet corn with speed of 400 cans/ min.

Each part of process are controlled well from raw material to package

Sweet Corn Peeling Machine

The Structure of Peeling Machine

The motor is installed on the power seat, the driving shaft is installed on the bearing seat, the driving shaft is connected to the motor through a belt,

and the driving shaft is provided with spiral bars and rubber nails.

The driving shaft is matched with the driving shaft through a gear.

The rubber wheel is sleeved on the drive shaft. The bearing seats at both ends of the driving shaft are not on the same level.

Sweet Corn Peeling Principle

The driving shaft is equipped with spiral strips and rubber nails, and the transmission shaft is equipped with multiple rubber wheels, the driving shaft and the transmission shaft cooperate with each other, and the peeling device can evenly distribute the cob that have entered the machine to relative rotating peelers. When the cob rotating itself, it move forward smoothly. During the movement, the peels are torn apart by the special peeling claws, and the peel is pressed down by the rotating shaft in an instant to complete the peeling.

Peeling Complete Rate

The corn peeling machine mainly includes the main body, the body is equipped with a feed inlet, and the power seat is connected with the body.

The peeling complete rate is 80%-95%,

The crushing rate is less than 1%,

The loss rate is less than 2%

It complete the corn peeling operation well, instead of manual operation, and improve work efficiency.

Sweet Corn Threshing Machine

Sweet corn threshing machine application

Threshing rate : 98%

We can see that canned sweet corn kernel , IQF sweet corn kernel, canned sweet corn cream are only made of corn kernel.

Corn threshing machine is the device to thresh kernel from corn cob. This is the starting of canned or IQF or cream corn production.

Sweet Corn Rolling Drum Cleaning Machine

Rolling Drum cleaning Machine

The size is customerized according to the capacity per hour

Machine is made of SUS304 stainless steel rolled pannel with hole on it.

The hole size is 2mm to remove the crushed corn kernel.

With spiral pannel inside for moving the corn kernel forward.

It has multiple functions, remove the whiskers, cores and other impurities and finally get the genuine corn kernels

Blanching Machine

Blanching machine is for pre-cooking

Machine is made of SUS304 stainless steel with conveying chain, with temperature monitor.

The size is customerized according to the capacity per hour

Pre-cooking temperature : 85-90 ℃, 3-5 minutes

For canned sweet corn production, there is no need cooling, because when sealing ,we have to make sure the middle temperature of filling can not less than 85 ℃

Sweet Corn kernel Filling Machine

This machine adopts quantitative measuring cup for precise quantitative filling, made of SUS304 stainless steel, Automatic control of the feeding, no filling without cans

The main specification of sweet corn kernel filling machine

| Item | Spec. | |

| Filling Head | 24 heads | |

| Capacity | 100-400 cans per min | |

| Applicable can diameter | D 52-153mm | Different diameter requires different parts |

| Applicable can height | H 39-178mm | |

| Dimension | 1680 x1900x2100mm | |

| Power | 1.5kw | |

| Weight | 1500kgs |

Canned sweet corn soup filling and seaming machine

This machine is advanced filling and seaming machine. It is designed based on absorbing domestic and foreign advanced technology .

It is mainly used in filling and seaming non-carbonated drinks like fruit juice, or canned food for soup filling and seaming .

Here we used it for filling soup and seaming for canned sweet corn

The sealing is double seaming spinning forming, frequency conversion speed control, with characteristic of stable filling, high speed, accurate filling volume, no cans no filling, no dripping, automatic control of the liquid level in filling tank.

And the filling tank can be connected with CIP (if factory have ) for cleaning and disinfection. The production speed is continuously adjustable.

|

Filling and Seaming machine for canned sweet corn canning line |

|||||

|

No. |

Item |

WMGT-12-4 |

WMGT-18-4 |

WMGT-24-6 |

WMGT-36-6 |

|

1 |

Seaming Heads |

4 |

4 |

6 |

6 |

|

2 |

Filling Heads |

12 |

18 |

24 |

36 |

|

3 |

Capacity |

80- 150 cans / min |

100-250 cans / min |

100 ~ 300 cans / min |

200 ~ 400 cans / min |

|

4 |

Applicable can height |

39 ~ 170mm |

39 ~ 170mm |

39 ~ 170mm |

39 ~ 170mm |

|

5 |

Applicable can Diameter |

52.3 ~ 99mm |

52.3 ~ 99mm |

52.3 ~ 99mm |

52.3 ~ 99mm |

|

6 |

Compressed Air |

0.6MPa |

0.6MPa |

0.6MPa |

0.6MPa |

|

7 |

Power |

7.5Kw |

7.5Kw |

11kw |

11kw |

|

8 |

Dimension (mm) |

2800 x 1500 x 2200 |

3100 x 1800 x 2200mm |

3500 x 1950x 2200mm |

4600x 2300 x 2200mm |

|

9 |

Weight |

3.5T |

4T |

5.5T |

6.7T |

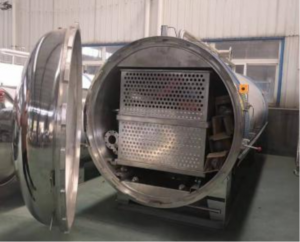

Retort Pot for Sterilization

Retort Pot (Sterilization Mahcine)

1 Uniform water exchange mode realizes uniform temperature without dead angle.

2 High temperature instant sterilization.

3 High sterilizing precision.

4 Energy saving.

5 All of the sterilizing courses can be controlled by computer PLC.

6 The sterilizing retort adopts simulative temperature control system,and multilevel heating system can be set.

7 The function of F value measurement.

Technicial Parameters

|

Item name |

Specification |

| Inner diameter/tube length/net volume (retort sterilizer) | 1200mm/2000mm/ about 1.57 cbm |

| Heating way | Steam |

| Maximum work pressure | 0.3Mpa (design pressure:0.35Mpa) |

| Maximum work temperature | 143 ℃(design temperature:147℃) |

| Total installed power | About 15kw |

| Power voltage | 380V /50Hz(customizable) |

| Retort Material | Sus304 |

| thickness of retort body | The inner wall is 10mm thick and the outer jacket is 5mm |

| Floor space size | About 4855mm*1630mm*2157mm |

| Weight (empty ) | About 2500kg |

We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation for Chinese wholesale Automatic Canned Beans Canning Line Beans Canning Production Line Machinery, We sincerely welcome consumers from both at home and overseas to come to negotiate company with us.

We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation for Chinese wholesale Automatic Canned Beans Canning Line Beans Canning Production Line Machinery, We sincerely welcome consumers from both at home and overseas to come to negotiate company with us.

Chinese wholesale China Canned Food Machinery and Canning Machinery, We are going to initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our products or would like to discuss a custom order, make sure you feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future.