Vacuum Nitrogen Flashing Sealing Machine / Can Sealer / Automatic Metal Can sealing

Product Application

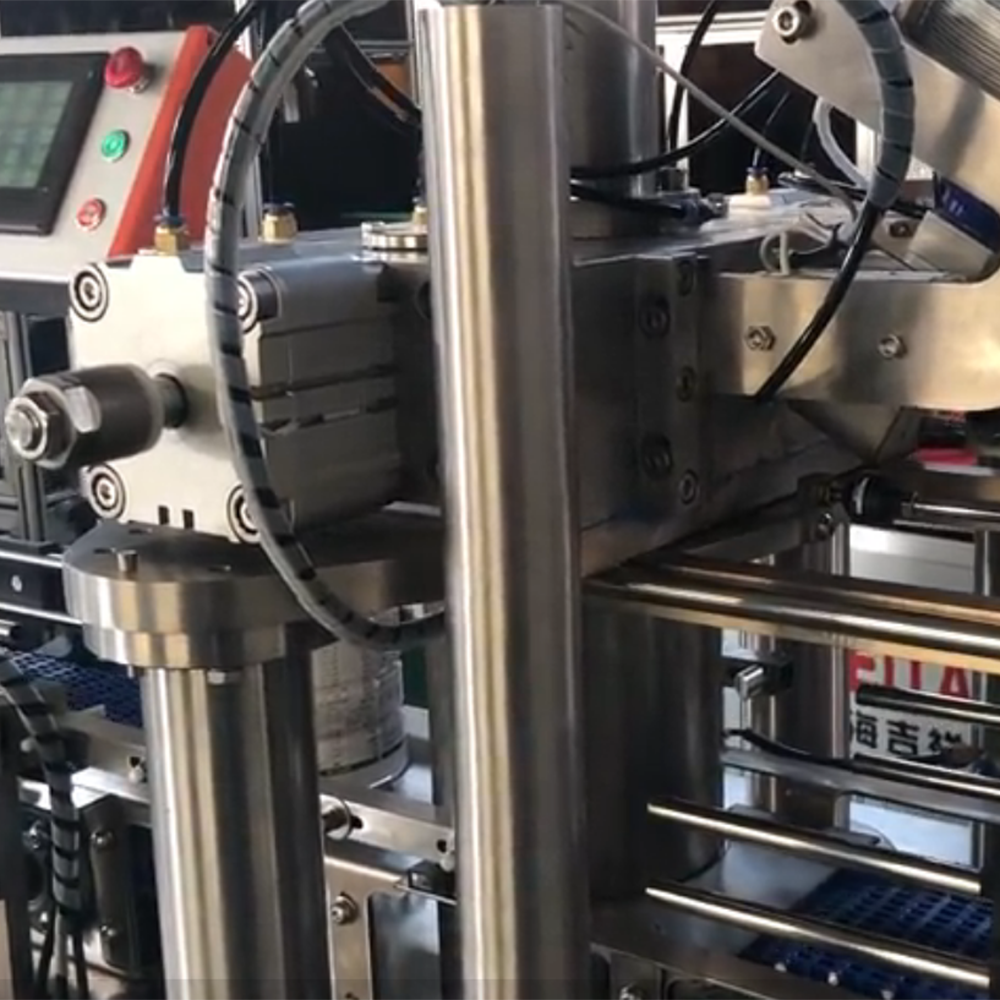

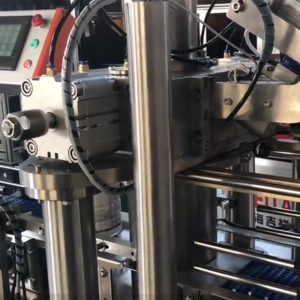

This is the latest Vacuum and Nitrogen Charging Powder seaming machine. It is automatic can-in,can-out,vacuum,nitrogen flushing and seaming.

The main electric components adopt “Mitsubishi” PLC, frequency converter, proximity sensor and “Siemens” analog output. Setup the production speed on touch screen. Machine alarms automatically of all common malfunctions and show the cause and position of malfunction, PLC detect and decide to continue or stop the machine according to the malfunction degree.

It is in great shape,steady running, low remaining oxygen value and high automatic. Touch screen operation, and the whole seaming process happens in sealed chamber which is reach to food production sanitation.

With reliable quality and easy operation, it is ideal equipment necessary for industries like canned powder food, canned pharmacy and chemical .

Together with filling machine , it can improve your capacity.

Usually, our customers used this seaming machine for milk powder packing, coffee powder packing , protien powder packing and other powder food products .

Technical Parameters

Double Head Automatic Vacuum Nitrogen Seaming Machine For Metal Can

|

No. |

Item |

Unit |

Paramaters for 1 head |

Paramaters for 2 heads |

|

|

1 |

Capacity | LN2 Dosing Mode |

can/min |

6~7 |

12-14 |

| Normal Mode |

can/min |

10 |

20 |

||

|

2 |

Residual amount of oxygen |

% |

<3% |

<3% |

|

|

3 |

Seaming Head |

head |

1 |

2 |

|

|

4 |

ApplicableCan Size | Can Height |

mm |

D73~D126.5 (300~502) |

D73~D 126.5 (300~502) |

| Can Diameter |

mm |

100-190 |

100-190 |

||

|

5 |

Compressed air consumption |

m3/min |

0.3 |

0.5 |

|

|

6 |

Compressed air requirements |

|

0.6~0.8MPa; D8 air pipe |

0.6~0.8MPa; D10 air pipe |

|

|

7 |

Nitrogen consumption |

L/can |

15 |

30 |

|

|

8 |

Nitrogen Requirements |

|

0.2~0.4MPa |

0.4~0.8MPa |

|

|

8 |

Main Power |

Kw |

4(Including vacuum pump) |

3.5+5.5 (Including vacuum pump) |

|

|

9 |

Votage |

|

3 Phase 380V/50HZ |

3 Phase 380V/50HZ |

|

|

10 |

Weight |

kg |

700 |

900 |

|

|

11 |

Dimension |

mm |

1900×850×1700 |

2060×1050×1700 |

|