Europe style for Hot Melt Glue OPP Labeling Machine for Bottles

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for Europe style for Hot Melt Glue OPP Labeling Machine for Bottles, Honesty is our principle, expert operation is our perform, support is our goal, and customers’ fulfillment is our future!

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for China Carton Box Sealing Machine and Hot Melt Glue Machine, We’ve been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we have the whole capacity to supply you happy solutions.

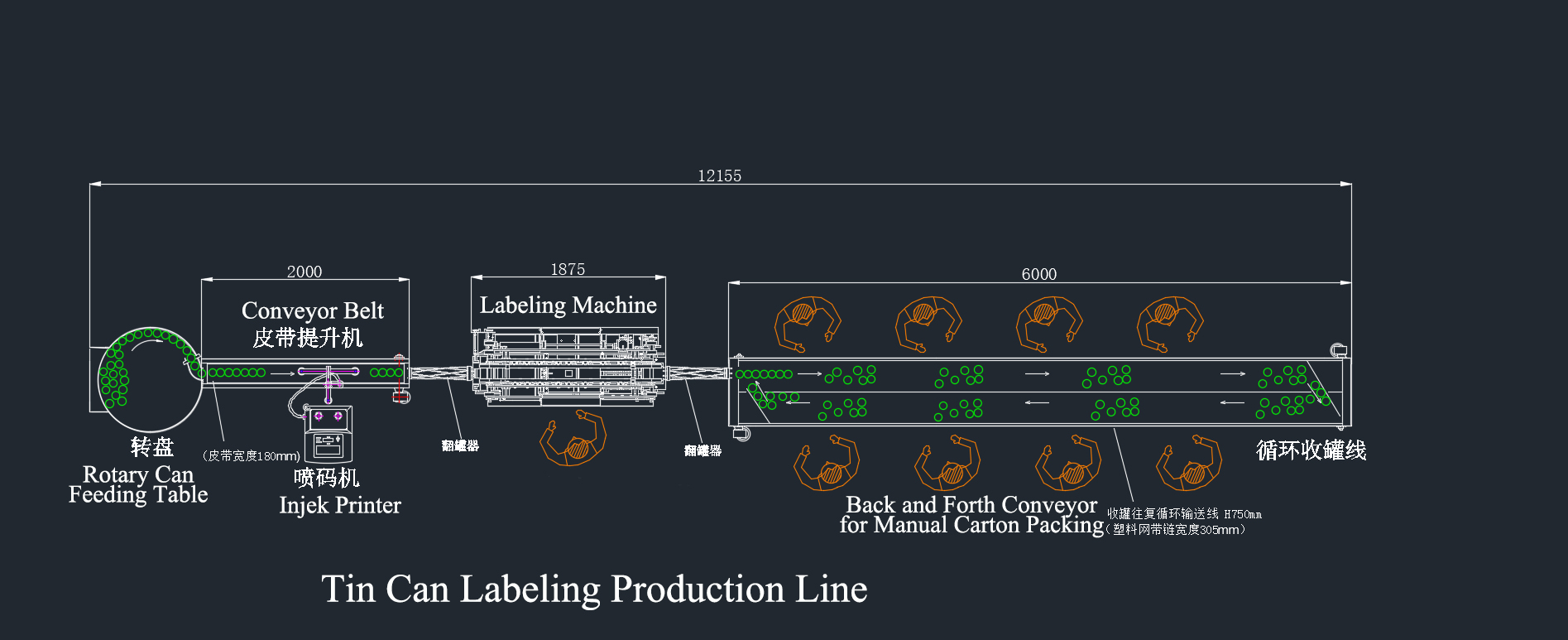

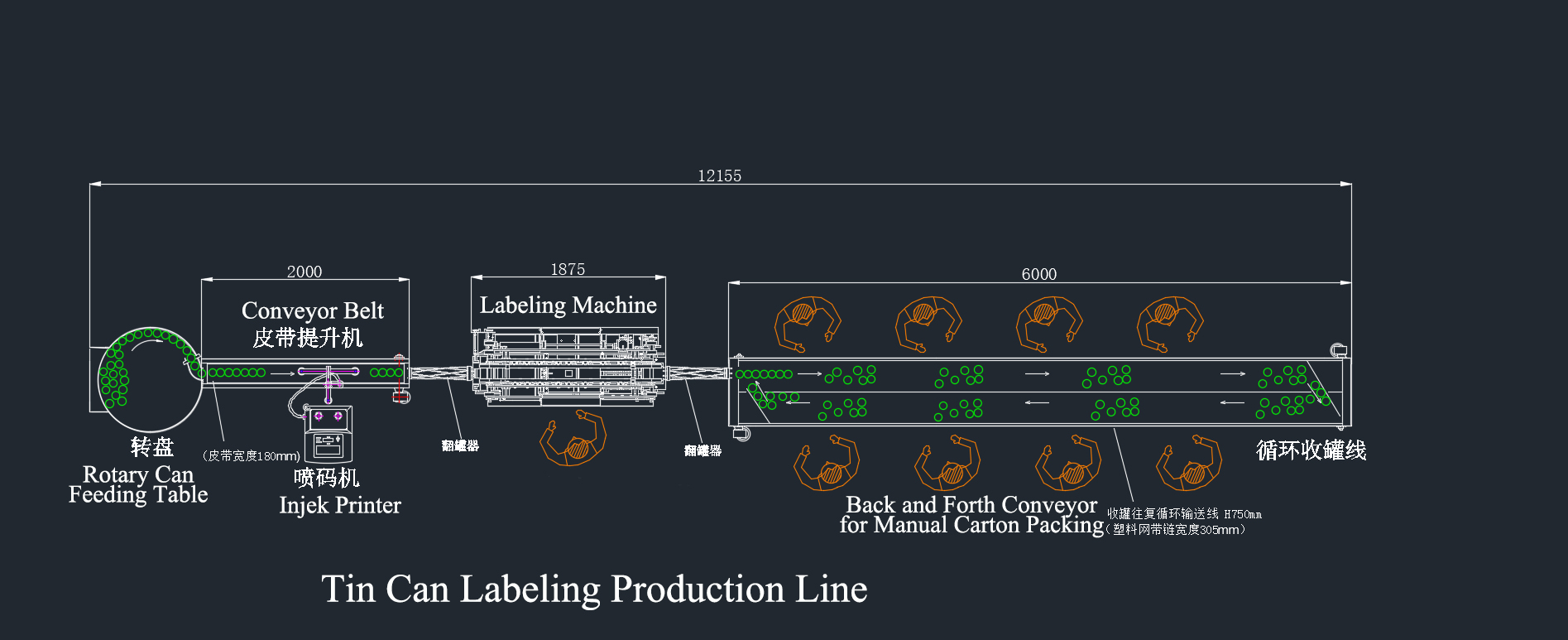

Specification of labeling machine

This machine is used for tin can labeling

Tin cans are rolling forward for lableing which increase the labeling speed compared to the traditional one.

This labeling machine combined with inkjet printer

1. Capacity range (cans/min) :200-400

2. Applicable can diameter(mm) : 50-114

3. Applicable can height(mm) : 30-240

4. Label dimensions(mm): L160 – 370, W25 – 236

5. Suitable glue :Hot melt glue,quick-drying glue

6. Power supply : 380V, 3 phase, 50hz

7. Power (kw) : 3kw

8. Air Compress: 2-4 kg/m2; 10 liters/minute

9. Dimensions(m) : accordign to the drawing, Total Weight : 900kgs

Special Features of labeling machine

1. After the can is rolled into the machine, the belt drive the can rolling. When the can passing through the hot melt adhesive station, they are coated with hot melt. With the can moving forward, the part with adhesive touch the front of the label and it began to be rolled on the can. At the same time, the glue at the end of the label will also work. As the cans moving forward, the labels are rolled over the cans. And then driven by the belt and roll out of the machine.

2. The machine has alternate label supplement system, so it don’t need to be turned off when adding labels.

3. The glue adding at the end is controlled by cans, it only adds glue when there is can.

4. The machine adopts frequency conversion speed control, which can be adjusted according to production needs at any time.

5. If the machine need adjustment for different cans, the replacement is simple.

6. The glue is only at the both ends of label, which can reduce the cost of labeling.

7. Easy to operate and clean.

Professional Canned food and beverage Machinery Manufacturer

Canned Sweet Corn Production Line (5-10 tons /hour available)

Canned Mackerel/Sardine/ tuna production line ( Capacity 60-80 tons/day available)

Canned Sardine production line (Capacity 60-80 tons/day available)

Canned Tomato Paste Production line ( capacity 3-100T/h available)

Canned beans Production line (Capacity 100 -400 cpm available)

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for Europe style for Hot Melt Glue OPP Labeling Machine for Bottles, Honesty is our principle, expert operation is our perform, support is our goal, and customers’ fulfillment is our future!

Europe style for China Carton Box Sealing Machine and Hot Melt Glue Machine, We’ve been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we have the whole capacity to supply you happy solutions.