Manufacturing Companies for China Standard 330 Ml Beer Beverage Aluminum Can Filling Sealing Machine

We pursue the administration tenet of “Quality is exceptional, Assistance is supreme, Reputation is first”, and will sincerely create and share success with all clients for Manufacturing Companies for China Standard 330 Ml Beer Beverage Aluminum Can Filling Sealing Machine, The mission of our firm would be to deliver the very best high-quality products and solutions with most effective value. We’re hunting forward to doing company with you!

We pursue the administration tenet of “Quality is exceptional, Assistance is supreme, Reputation is first”, and will sincerely create and share success with all clients for Beer Filling, China Beer Filling Machine, We will initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our products or would like to discuss a custom order, remember to feel free to contact us. We have been looking forward to forming successful business relationships with new clients around the world in the near future.

PRODUCTION DESCRIPTION

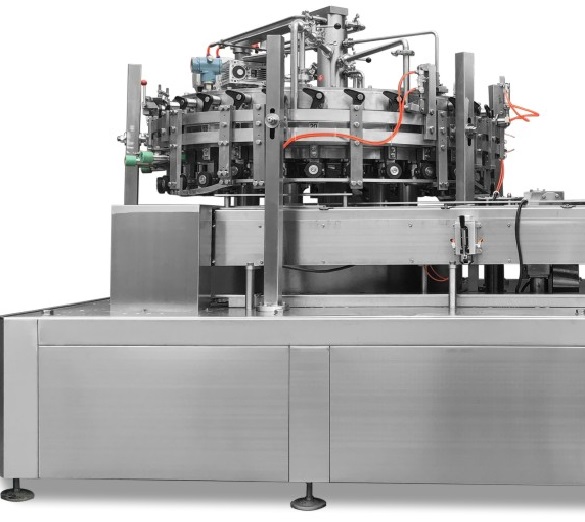

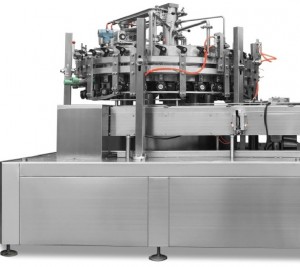

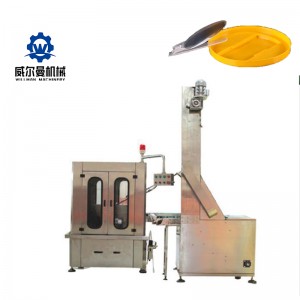

18000 CPH 250ml / 330ml /500ML Aluminum can carbonated drinks Filling Sealing Machine production Line

This machine is suitable for aluminum can filling and sealing carbonated soft drinks or beer .

It is equipped with the advanced device, electrical equipment, and pneumatic control technology.

It has the characteristics of filling accurately, high speed, liquid level control, seaming reliably, frequency conversion timing, less filling content loss.

FIlling and seaming machine can be equipped with long-distance control system if customer require .

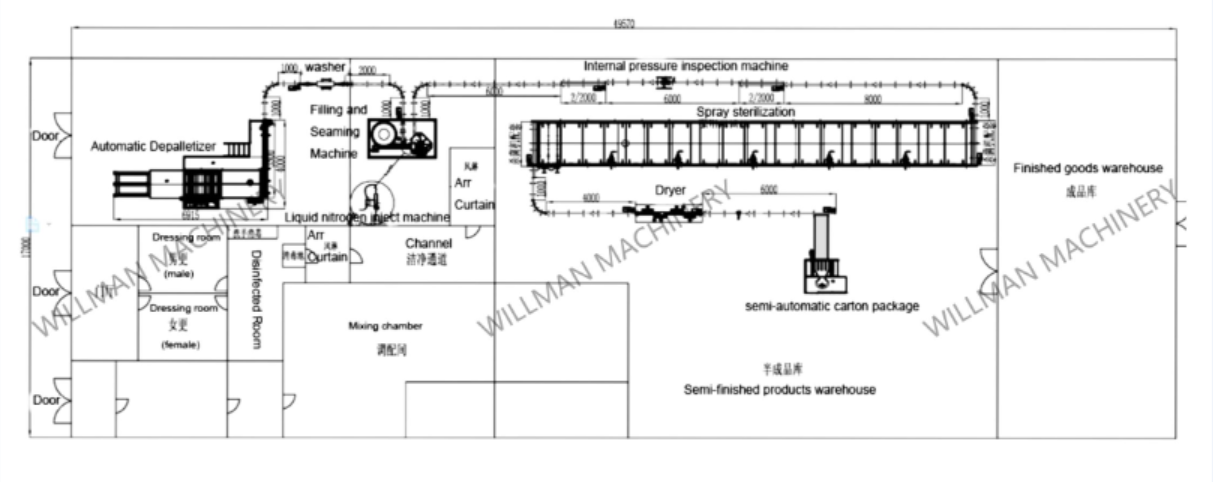

PRODUCTION PROCESS DESCRIPTION

Canning system starts from empty can depalletizing. Empty cans can be depalletized from pallet by pushing them one layer by one layer .

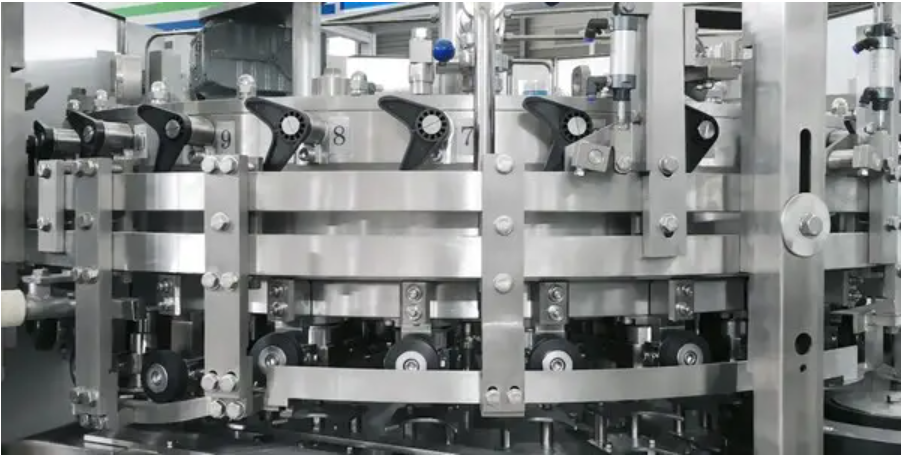

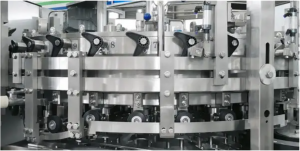

Cans will be spraying washed in screw type tunnel and going ahead for filling . Centering cup of filling valve will fall to cans.

When cans fit into the filling position, the filling valves and top of cans will be sealed by rubber type ring.

The movement of centering cup is generated by plastic idler wheel along curvilinear motion.

After filled, valve will be closed, air is discharged, and centering cup will rise from the can.

Filled can will be sent to conveyor chain, then to capper.

Capper will take cap, turn over the edge of can and turn the edge to finish the sealing action by the control of cam.

After that can will be transferred to conveying system to next precess -pasteurization.

CONFIGURATION

| 1. PLC | Mitsubishi |

| 2. Main motor | ABB |

| 3. Pneumatic component | Airtac |

| 4. Touch screen | Proface |

| 5. Inverter | Mitsubishi |

| 6. Breaker | Siemens or Schneider |

| 7. Contactor | Siemens or Schneider |

| 8. Proximity switch | Sick |

| 9. Photoelectric switch | Sick |

| 10. Lubrication bearing | Igus |

TECHNICAL PARAMETERS

| Model | Capacity | Overall dimensions | Filling heads | Sealing heads | Power | Weight |

| WM12-4 | 150 cans/min |

3350*2150*2100 mm |

12 | 4 | 3.5 kw | 3500 kg |

| WM18-4 | 200 cans/min | 3500*1950*2000 mm | 20 | 4 | 5.5 kw | 4000 kg |

| WM24-6 | 200 cans/min | 3560*2150*2100 mm | 24 | 6 | 6.5 kw | 5300 kg |

| WM36-6 | 300 cans/min | 4600*2300*2200 mm | 36 | 6 | 7.5 kw | 8000 kg |

PRODUCTION LINE DRAWING

We pursue the administration tenet of “Quality is exceptional, Assistance is supreme, Reputation is first”, and will sincerely create and share success with all clients for Manufacturing Companies for China Standard 330 Ml Beer Beverage Aluminum Can Filling Sealing Machine, The mission of our firm would be to deliver the very best high-quality products and solutions with most effective value. We’re hunting forward to doing company with you!

Manufacturing Companies for China Beer Filling Machine, Beer Filling, We will initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our products or would like to discuss a custom order, remember to feel free to contact us. We have been looking forward to forming successful business relationships with new clients around the world in the near future.