With the continuous growth of people’s income, the gradual change of consumer attitudes, and the diversification of purchasing channels, soft drinks have become a commodity for many people’s daily consumption, and the market size is also expanding. Based on this, advanced aseptic filling lines are also widely used in the field of food and beverages, which can not only meet the requirements of the container period, but also maintain the taste, color and flavor of the product, and have a high degree of flexibility. switch to meet the diversified consumer needs of market segments.

In recent years, China’s soft drink industry has shown a good growth trend. However, although the size of China’s soft drink market in 2019 exceeded 991.4 billion yuan, the market is also becoming saturated. In terms of product attributes, domestic mainstream consumer groups have gradually transitioned from carbonated beverages to packaged water, and then to healthy beverages such as milk-containing beverages, compound protein beverages, probiotic-containing beverages, and tea beverages. Market segments such as beverages may become new growth points in the industry in the future.

It is not difficult to find that although the soft drink market is becoming saturated and the growth rate of the market size has gradually slowed down, the consumption demand of the beverage market segment still has great potential and the sub-categories are more diversified. Functional beverages are beverages that adjust human body functions to a certain extent by adjusting the composition and content ratio of nutrients in beverages, while milk-containing beverages use fresh milk or dairy products as raw materials and are fermented or unfermented. With the continuous improvement of the concept of healthy eating, it has attracted more and more attention from the market.

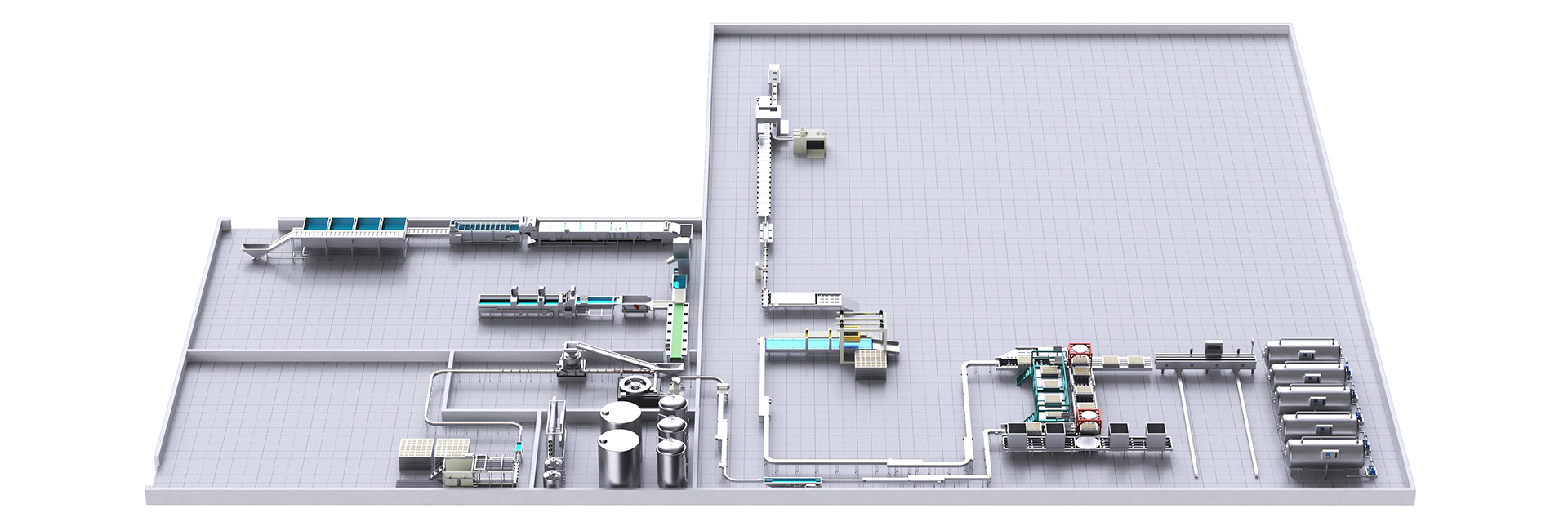

In this context, beverage processing enterprises are also accelerating the reconstruction, expansion or new construction of beverage production lines, improving the level of beverage filling production equipment, accelerating product output expansion and improving product quality. Among them, in the construction of production lines, the aseptic filling production line has the incomparable advantages of traditional equipment and is favored by many enterprises. The aseptic filling line enables beverage products to be filled into aseptic containers in an aseptic environment and sealed without adding preservatives, and allows the products to obtain a longer shelf life at room temperature. Aspetic liquid nitrogen dosing machine is necessary for soft package.

According to the author’s information, a beverage processing enterprise plans to invest about 200 million yuan in total, investing in the construction of 3 aseptic filling production lines for milk-containing beverages, and supporting the construction of warehouses and other ancillary facilities. After the implementation of the project, it will help to further improve the company’s beverage filling production equipment level, expand product output, improve product quality, and continuously meet consumer demand for products. It is said that the production line is an advanced aseptic automatic processing equipment, and a subsequent intelligent packaging production line.

Specifically, the aseptic cup filling production line also uses the current advanced magnetic levitation flexible conveying technology. The whole line consists of automatic cup grabbing equipment, online positioning and coding and straw sticking equipment, intelligent visual inspection and rejection equipment, and circular magnetic levitation conveying. The system, wrapping products and automatic packing equipment for single-cup products, automatic palletizing equipment, etc., can release 24,000 cups of production capacity per hour. In addition, the production line has a high degree of flexibility, and 18 different packing specifications can be switched by one-click menu, which maximizes the efficiency of the production line.

Aseptic filling has incomparable advantages in beverage nutrition, preservation and quality. With the improvement of modern filling technology and the diversification of healthy beverage market demand, the comprehensive performance of aseptic filling has been continuously improved, and the level of flexibility and intelligence has been continuously improved. While improving the efficiency of the production line, it will also meet the trend of diversified beverage consumption. In the future, aseptic filling will gradually replace ordinary filling as the main method of beverage packaging.

Post time: Apr-01-2022