Fruit juice Canning Production Line machinery manufacturer polupar in Vietnam

Product Description

Willman Machinery-- Professionan canned food and beverage machinery manufacturer from China .

With 15 years experience ,we provide whole production line for arious types of canned food or canned beverage, carbonated or non-carbonated drinks .

We have got rich experience for whole production line solution for fruit juice Canning Production line by providing many whole canned fruit juice production line for our customers and got good reputation.

Let's have a what machines this fruit juice canning production line consists of.

Fruit juice Canning Production Line --- Empty Can Depalletizing Machine

Automatic metal can depalletizing machine is used at the start of beverage canning production line.

It is used for depalletizing empty metal can from full and high stacked can on pallet automatically, which improve the production

efficiency for filling and satisfy customers’ beverage production.

1. Capacity :0-600 cans per minute

2. Applicable container : aluminum can , tin can , glass bottle

3. Applicable can height : 39-240mm

4.Dimension :4950*2500*4500mm

5. Suitable for pallet size : 1.1m *1.4m /1m *1.2m

6. Power supply : 380V 3phase 50hz

7. Total power :5 kw

8. Total weight :4.5T

9. Noise :<85dB

10. Operator : 2 persons

Fruit juice Canning Production Line --- Empty Can Washing Machine

This empty can washing maachine is water spraying type.

Empty can will be upside down conveying through spraying water under and then turn back to right position for filling

Capacity: 200-400 cans per minute

Material: SUS304 stainless steel

Dimension: 2400×2000×500mm

Fruit juice Canning Production Line --- Fruit Juice Filling and seaming machine

drink and canned food, The capacity is 100-300 cans per minute.

The machine is combined with two parts:filling and sealing. The filling part is using the normal pressure filling method. The

liquid level is controlled by the liquid level filling principle. Both normal temperature filling and high temperature filling can

be adapted.Filling head: 36 heads,

Seaming head: 6 heads

Capacity: Max. 350 cpm

Range of diameter: 52.5-99mm

Range of height: 70-133mm

Dimension: 2.8M*1.7M*1.95M

Weight: 5500 kg

Power: 7.5 kw

|

Model

|

WM-12-1

|

WM-18-1

|

WM-18-4

|

WM-24/6

|

WM-36/6

|

|

Application

|

Craft beer, carbonated drinks, gas beverage, sparkling water, cider, soda water

|

||||

|

Packing Type

|

Aluminum cans, tin cans, pet cans, etc

|

||||

|

Capacity

|

2000CPH(12oz)

|

2000CPH(1L)

|

3000-6000CPH

|

4000-8000CPH

|

18000 CPH

|

|

Filling Range

|

130ml, 250ml, 330ml, 355ml, 500ml, 12oz, 16oz, 1L and so on (0.1-1L)

|

||||

|

Power

|

0.75KW

|

1.5KW

|

3.7KW

|

3.7KW

|

7.5KW

|

|

Size

|

1.8M*1.3M*1.95M

|

1.9M*1.3M*1.95M

|

2.3M*1.4M*1.9M

|

2.58M*1.7M*1.9M

|

2.8M*1.7M*1.95M

|

|

Weight

|

1800KG

|

2100KG

|

2500KG

|

3000KG

|

5500KG

|

Fruit juice Canning Production Line --- Liquid Nitrogen Dosing Machine

When producing fruit juice (no - carbonated ) in aluminum can, Liquid Nitrogen Dosing Machine is necessary.

Lqiuid nitrogen dosing machine strength the light package

Liquid nitrogen will turn into gas when it touches anything warmer than itself. It expands to gas 700 times its volume

A drop of liquid nitrogen into the head space of a filled aluminum will purge the air out leaving only nitrogen. By using liquid

nitrogen dosing, the residual oxygen left in the headspace can be reduced to as little as 0.5%.

300 cans per min, Set up continuous dosing speed

Suitable Can Size: According to customer’s requirement

Power :200W

Voltage :380V 50HZ 3 phase

Weight :32kg

Dimension :1300mmx750mmx450mm

Fruit juice Canning Production Line --- Pasteurization Tunnel

Pasteurization tunnel is water spraying type bottle warming/cooling machine.

Fruit juice Canning Production Line --- Internal Pressure Detection Machine

Internal pressure detection after sealing to make sure every aluminum can sealed well without leakage

Capability:1200 cans/min

Test applicable pressure range: 0-6bar

Dynamic accuracy is better than 0.05bar

Static accuracy detection: 0.01bar

Test accuracy: 99.99%

Missing kick rate less than 0.01%

Sensor Precision is better than 0.01bar

* Compressed air: Used to supply the elimination of cylinders. Need 8mm diameter air tube, pressure range of 4-6 kg

Fruit juice Canning Production Line --- Coding Machine

It can realize 32 dot matrix jet printing, the circuit system, ink system and nozzle are innovative design to reached the

higher stability.

* Spray printing parameters and the information content are in storage integration, which is

* convenient for user to find at any time, reducing waste of time and improving work efficiency.

* The design can be directly edited by computer. And information, design,

* and word library can be imported or exported through using USB.

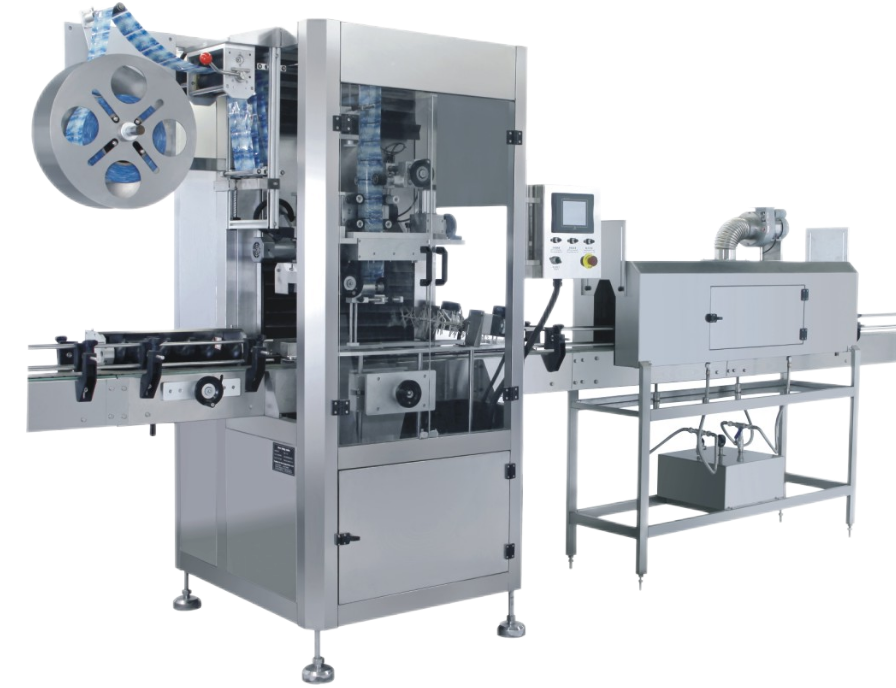

Fruit juice Canning Production Line --- PVC heating Shrink Labeling Machine

* The Sleeve System is a fully automatic shrink sleeve labeling system for applying and shrinking full body sleeve labels. Each Sleeve System includes a sleeve applicator, one or two shrink tunnel modules, (depending on the requirement), a steam generator and a stainless steel conveyor for transporting containers through the system.

Fruit juice Canning Production Line ---Automatic Shrink Wrapping Machine / Package Machinery

* Automatic shrink wrapping machine is suitable for wrapping beverage can or bottle, mineral water bottle, beer package. It is PE film shrink wrapping, cost saving package without carton or paper tray. The wrapping and heating tunnel is working stably and stable capacity with good performance.

Willman Machinery Company introduction