Canned Coconut Milk Production Line Srilanka

Canned Coconut Milk Production Line

Coconut milk is healthy, vegan alternative to dairy milk. Coconut milk does not contain lactose and is lower in carbohydrates than dairy milk, which can be consumed by people who are lactose-intolerant or just don't enjoy the taste of dairy milk. Although regular canned coconut milk is higher in calories and fat than whole dairy milk, the plant-based saturated fat in coconut milk may provide health benefits not found in the animal-based saturated fat in dairy milk.

It is also a rich source of Iron and Copper. Furthermore, coconut milk is lower in sugar than dairy milk, which is beneficial to limit carbohydrates in diet. Coconut milk has tremendous importance especially in Ayurvedic traditional medicinal purposes. It is generally used to maintain the electrolyte balance and to rule out dehydration losses. Also, it is used for treatment of ulcers in the mouth. Some recent studies have suggested that coconut milk has anti-microbial properties in the gastrointestinal tract, hyperlipidemic balancing qualities and useful for topical applications.

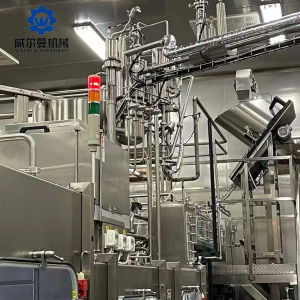

Canned Coconut Milk Production Line Machine and process

After coconut milk pre-prossing, it keep in storage tank. When canning line starting, coconut milk pump to filling tank.

1. The empty tin can depalletizer as the start of this canning line .

Empty tin can depalletizing machine is automatic equipment for depalletizing empty tin can from high pallet package easily. Through lifting the pallet, the tin can can be push our from pallet to the muti-line conveyor and moving forward to single line conveyor belt for empty tin can washing .

2. Coconut milk filling and seaming machine monoblock.

This is a monoblock with function of vacuum at seaming part. The filling is gravity filling for tin can with big opening. Volume precisioncan be control as ±2ml.

Please replace the spring and sealing ring after 1-2 years running.

3. Sealed can washing machine

Washing the cans after filling and seaming to keep the cans from spot after sterilization.

4. Basket loading for sterilization

5. Retort pot for sterilization

6. Basket unloading machine after sterilization

7. Sealed can palletizing after sterilization for incubation for 5-7 days

8. After 5-7 days of incubation and check the quality of canned coconut milk,

then go ahead for coding and labeling and final packing in carton. This is the whole canning production line for canned coconut milk.