Canned Juice Machine Filling and sealing machine juice canning production line Vietnam

Brief Introduction

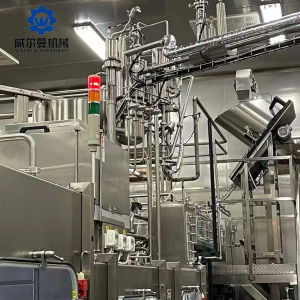

Canned Juice machine filling and sealing machine on juice production line

Canned food machinery canned food Filling and sealing Machine

Easy operation

High speed

Good performance

Qualified sealing structure

Convenient maintenance

1. More reasonable and beautiful overall structure

2. Obvious bigger seaming head, adopt heavy bearing which prolong the seaming cam service, the normal service time prolong 5 times.

3. Twin shafts structure: The first seaming roll and the second seaming roll are separated. User could adjust and control the seaming rolls separately.

4. The rotation direction is anticlockwise direction in seaming process; the capped cans leave the capping part automatically as its direction to avoid jam and scratch.

5. Filling cylinder is arc structure, no dead angle to avoid liquid left. It adopts CIP automatic clean design to clean without tear apart the filling heads after working.

This machine is the equipment which designed and produced on the basis of 30 years beverage packing experience.

It adopts ordinary filling principle, and the main electric components adopt import products, like“Siemens” PLC, “Delta” frequency converter and “Omron” proximity sensor and “Siemens” analog output. It is high speed of filling,running steady,high quality seaming,pleasing appearance,convenient for use and maintenance,touch screen operation,frequency control and the distances between liquid level and rim of can are consistent. It is ideal equipment for beverage factories and food plants.

The user could setup the production speed on touch screen. Machine alarms automatically of all common malfunctions and shows the cause and position of malfunction, PLC detects and decides to continue or stop the machine according the level of malfunction.

The machine is advanced filling and seaming machine. It is designed based on absorbing domestic and foreign advanced technology .

It is mainly used in filling and seaming non -carbonated drinks like fruit juice, canned food for soup filling and seaming .

The sealing is double seaming spinning forming, frequency conversion speed control, with characteristic of stable filling, high speed, accurate filling volume, no cans no filling, no dripping, automatic control of the liquid level in filling tank.

And the filling tank can be connected with CIP (if factory have ) for cleaning and disinfection. The production speed is continuously adjustable.

Technical Paramaters

Juice Canning machine juice canning production line

Canned food machinery canned food Filling and Seaming Machine

|

Full Automatic Complete Fruit Juice Canning Line |

|||||

|

No. |

Item |

WMGT-12-4 |

WMGT-18-4 |

WMGT-24-6 |

WMGT-36-6 |

|

1 |

Seaming Heads |

4 |

4 |

6 |

6 |

|

2 |

Filling Heads |

12 |

18 |

24 |

36 |

|

3 |

Capacity |

80- 150 cans / min |

100-250 cans / min |

100 ~ 300 cans / min |

200 ~ 400 cans / min |

|

4 |

Applicable can height |

39 ~ 170mm |

39 ~ 170mm |

39 ~ 170mm |

39 ~ 170mm |

|

5 |

Applicable can Diameter |

52.3 ~ 99mm |

52.3 ~ 99mm |

52.3 ~ 99mm |

52.3 ~ 99mm |

|

6 |

Compressed Air |

0.6MPa |

0.6MPa |

0.6MPa |

0.6MPa |

|

7 |

Power |

7.5Kw |

7.5Kw |

11kw |

11kw |

|

8 |

Dimension (mm) |

2800 x 1500 x 2200 |

3100 x 1800 x 2200mm |

3500 x 1950x 2200mm |

4600x 2300 x 2200mm |

|

9 |

Weight |

3.5T |

5T |

5.5T |

6.7T |

|

Material |

Shape |

Lid Diameter |

Aluminum Can Size |

Filling Volume |

||||

|

Aluminum Can |

Round |

113# 200# 202# 206# |

180ml/ 250ml 330ml/ 355ml 475ml/500ml |

100-500ml or more |

||||

|

Production Capacity |

4800 -24000 Cans per minute |

|||||||

|

Parts for different diameter cans |

Customers need to buy additional parts for the different diameter cans. |

|||||||

|

Juice Pre-Production |

Juice mixing system , Water treatment, CIP |

|||||||

|

Production flow |

Empty can depalleting - Empty Can Washing - Filling - Seaming - Sterilization - Palletizing |

|||||||

|

Package Line |

||||||||

|

System |

Labeling Type |

Block Packing Type |

Block Style |

Palletizing system |

||||

|

|

Automatic rolling feed Labeling Automatic PVC shrink labeling |

Manual Film shrinker Wrap Around packe Robert Packing Machine |

1*2 2*3 3*4 4*6 3*5 |

Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer |

||||

|

Power Supply |

380V 3phase 50HZ or as requirement from different countries |

|||||||