Automatic Basket (cage) Loading and Unloading Machine

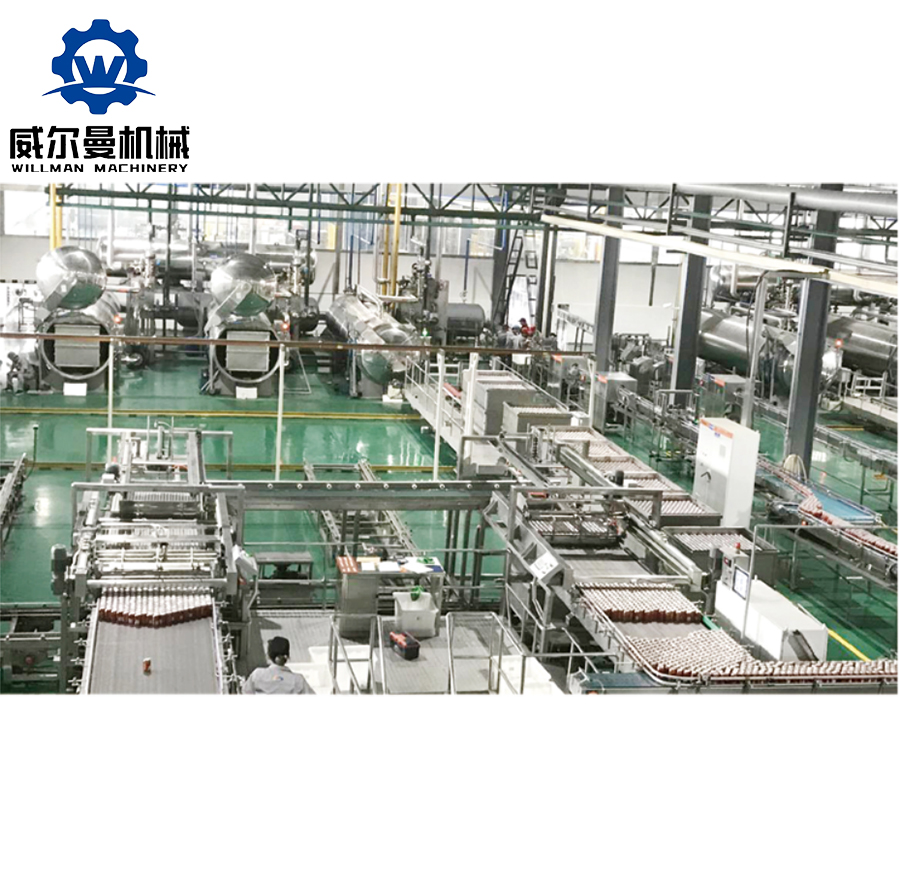

Product Application

This system is mainly used in various types of cans. The cans are automatically loaded in retort bakset before sterilization. The sealed cans are transported by the modular mesh belt conveyor, and the sealed cans are divided and arranged in a row. Cans are stacked in the sterilization bakset, and then transferred to the sterilization pot for sterilization through the bakset conveying system. The whole process is automatic.

Comparing to semi-automatic bakset loading machine, the process of stacking in basket and conveying bakset into retort pot has been upgraded as automatic one .

The plate is automatically put in, automatically raised, automatically divided and filled, automatically lowered, and automatically stops filling when the bakset is full. The perfect configuration mechanism replaces the manual filling method, saving manpower, greatly improving production efficiency.

Bakset Loading System

This system is used for automatic retort basket loading .

The cans are sent from the conveying platform to the loading platform, and the cans are manually loaded in basket with scrapers.

After the cans are filled with one layer, they are separated by a partition. At the same time, the hydraulic lifting table lowers by one layer, and another layer of loading is carried out until the sterilization basket filled fully.

The system consists of a hydraulic lifting platform, sterilization basket which is matched with the horizontal sterilizer), and a loading platform.

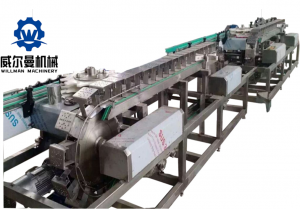

Bakset Unloading System

The system adopts a fixed hydraulic lifting platform for semi-automatic unloading of the sterilization basket:

The sterilized cans are unloaded from the hydraulic lifting platform after being pushed out by the push pannel.

The hydraulic lifting platform rises one layer, the cans are pushed out one layer, and sent out by the conveyor belt to the packaging platform.

This system consists of a hydraulic lifting platform, sterilization basket which is matched with the horizontal sterilizer, and an unloading platform.

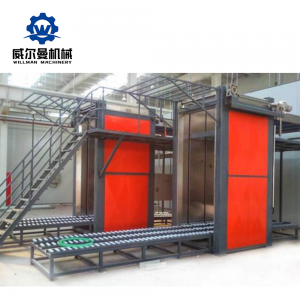

The main Technical Parameters

- Production capacity: 100-400 cans/min

- Motor power : 2.95kw ( bakset loading)

- Motor power : 2.75kW (bakset unloading)

- Weight: 1.1 T ( basket loading )

- Weight: 0.9T (basket unloading)

- Dimension: 7000 x 1100 x 1300 mm ( basket loading )

- Dimension : 4000 x 1100 x 1300 mm (basket unloading)