Special Price for 7000cph 8000cph Automatic Aluminum Can Flavor Water/Coconut Water/ Juice /Non-Carbonated Drink Beverage Canning Filler Seamer with High Quality

Our business since its inception, usually regards product or service high-quality as organization life, continuously boost production technology, improve solution top quality and repeatedly strengthen business total top quality management, in strict accordance along with the national standard ISO 9001:2000 for Special Price for 7000cph 8000cph Automatic Aluminum Can Flavor Water/Coconut Water/ Juice /Non-Carbonated Drink Beverage Canning Filler Seamer with High Quality, We maintain timely delivery schedules, modern designs, high-quality and transparency for our clients. Our moto would be to deliver high quality solutions within stipulated time.

Our business since its inception, usually regards product or service high-quality as organization life, continuously boost production technology, improve solution top quality and repeatedly strengthen business total top quality management, in strict accordance along with the national standard ISO 9001:2000 for China Filling Machine and Liquid Filling Machine, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

Carbonator

Main uses and characteristics

This machine is used to produce various carbonated beverages (mix of water, syrup, carbon dioxide) such as lemon, cola, fruit juice and soda. It is the main equipment in beverage production equipment (especially the key equipment for medium and high-end beverage production)

II Features:

1. Adopting advanced technology in the chemical industry, large gas-liquid mass transfer area, small resistance loss, high efficiency, low energy consumption, simple structure, and a multi-stage centrifugal pump with reliable performance and low noise, so that the overall performance Protection.

2. The machine is equipped with high-precision proportional needle valve and pneumatic angle valve in the syrup and water pipeline, which can accurately adjust the mixing ratio and prevent the syrup and water from flowing with each other. The action is sensitive and reliable.

3. The machine can easily adjust the gas content, and it can be adjusted through appropriate operations according to the requirements of the beverage gas content.

4. The machine is equipped with a complete automatic control system, which has the advantages of coordinated action, simple structure, continuous production, and high degree of automation.

Technical performance and basic parameters

1. Production capacity: 4000 LPH (customized for security requirements)

2. Adjustment range of syrup to water ratio: 1: 3 ~ 1: 10

3. Gas content: (CO2: H2O volume ratio)> 2.8

4. Mixing accuracy: ≤2%

5. Frozen water inlet temperature: 2 ~ 5 ℃

6. Frozen water inlet pressure: 0.01Mpa ~ 0.08MPa

7. Syrup inlet temperature: 2 ~ 8 ℃

8. Syrup inlet pressure: 0.01Mpa ~ 0.08MPa

9. CO2 inlet pressure: 0.7Mpa ~ 0.8MPa

10. Purity of carbon dioxide: > 99.9%

11. Working pressure of water storage tank and syrup tank: 0.04MPa

12. Working pressure of storage tank: 0.2Mpa ~ 0.5MPa

13. Total motor power: 4.5kw

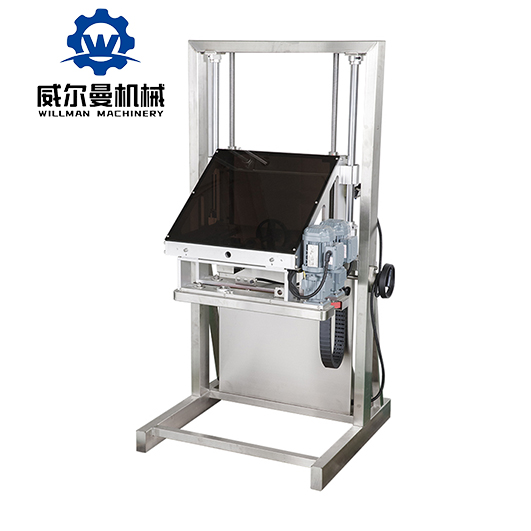

Automatic Aluminum Can Depalletizer

- Capacity : 200-600 CPM

- Applicable diameter

52-D153mm

52-D153mm - Applicable Height: 39~200 mm

- Cans Pushing Type: Automatic

- Cans output style: From multi-row to single row

- Lifting style: Automatic

- Dimension: 7.5×4.5×3.2 m

- Weight :3.5T

Slide type Rinsing Machine

Capacity: 200⁓400 CPM

Material: SUS304

Dimension: 2400×2000×500mm

Carbonated drinks 2 in 1 Filling and Seaming Monoblock

- Filling material:Carbonated Drink

- Applicable diameter

53-D66mm

53-D66mm - Applicable Height: 90~175 mm

- Filling temp. :0-4℃

- Filling valves number :32

- Seamer heands :

- Capacity:300CPM

- Air pressure:0.4MPa

- Compressed air consumption: 4Nm3/h

- Supplying pressure : 0.4MPa

- CO2 Requirement:Purity 99.995%

- Power :7.5KW

- Machine size :3550X2150X2000 mm

- Weight :6000Kg

Bottle Warming Tunnel for Carbonated Drinks

- Dimension: L=11M W=1.5M

- Product outlet temp.: 25-30℃

- water consumption: Recycling use material: SS304

- water tanks is heating by steam. With temp. control system.

- Function Description: it with three Temperature zones.

- water temp. zone : normal temp.(3.5meters)

- water temp. zone: cool water (3.5meters)

- water temp. zone: cool water (4meters)

- The material of conveyor chain: PP

- Motor + reduce: China famous brand

- Water pump: nanfang pump

- Machine frame: SUS304

- Contactors/protection: Schneider

Can Drying Machine

It is mainly used to blow the drips on the surface of the bottle after filling. It is useful to labeling machine.

Technical parameters:

Production capacity: 3000-6000 bottles / hour

Duct Length: 1600mm

Power :5.5kw

Dimensions:1600 × 350 × 1400mm

Internal pressure inspection machine

Inspect canned tank after filling liquid nitrogen, remove unqualified product with sound and light alarming

1.Weight: 150kg

2.Capacity : 50⁓300 CPM

3.Dimension: 2000×600×1400mm

Internal pressure inspection machine

1, Oversize : L16390xW1800x H2500mm

2. Shrinkage Tunnel Dimension: L2500 x W700 x H450mm

3. Max Package Dimension : L460mm*W280mm*H345mm

4. Packing Speed : 30pcs/min

5. Power: 60kw

6. Transfer Belt Width:686mm

7. Work Air Pressure : 0.6-0.8Mpa

8. Air Consumption: 80NL/min-100NL/min

9. Total Weight :5200kg

Our business since its inception, usually regards product or service high-quality as organization life, continuously boost production technology, improve solution top quality and repeatedly strengthen business total top quality management, in strict accordance along with the national standard ISO 9001:2000 for Special Price for 7000cph 8000cph Automatic Aluminum Can Flavor Water/Coconut Water/ Juice /Non-Carbonated Drink Beverage Canning Filler Seamer with High Quality, We maintain timely delivery schedules, modern designs, high-quality and transparency for our clients. Our moto would be to deliver high quality solutions within stipulated time.

Special Price for China Filling Machine and Liquid Filling Machine, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.