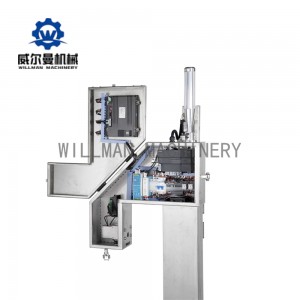

Vacuum Detection Machine For Can Filling Machine Production Line

Vacuum Detection Machine working procedure

1. Inspect the container through the electric eye, trigger magnetic eye photon beam.

2. When inspecting the container through sound probe, probe the high-energy magnetic pulse shock at the center of the lid.

3. Lid Makes a noise “dong”

4. The microphone receives the sound of "dong" and send the information to the voice processing system.

5. Equipment measures and compares the noise "dong", the container generating the pulse which beyonds the limitation setted by user will be removed.

Detail processing

1. Probe stent is humanized design, hand wheel can adjust height, manual knob adjust the front and rear.

2. Support the base anchor design, maintaining the surface cleanliness.

3. Probe the brace protection design, top seal, waterproof and dustproof.

4. Excluding system humanized design, before and after the handwheel adjustable height, convenient to change mold.

5. Magic eye stent humanized design, adjustable height before and after, convenient to change mold.

Strict factory inspection procedures before delivery

Detection machnie with any performance indicators that can not meet the technical requirements are allowed to delivery.

Below test will be compulsory completion before delivery :

(1)Components performance test

(2)The PLC program, the computer program test

(3)Safety protection test

(4) The machine continuous work

The chemical characteristics of vacuum detection machine

1. Non-contact on-line detection

2. Using double-head detection technology: Electromagnetic pulse acoustic scanning technology and surface scanning technology

3. Acoustic technology plus scanning technology

The different degree of vacuum will cause a small difference in the surface tension of the tank, which can accurately judge the quality of the vacuum according to the characteristics of the audio signal which vibrates on the tank surface.

4. Surface detection technology: with sound wave to achieve complementary detection, detection of expansion tank inspection, reverse tank

5. Vacuum inspection, expansion tank inspection, reverse tank detection

6. Applicable to conveying speed: 70m/min

7. Maximum speed: 1200cans/min

8. Weight:50kg

9. To automatically remove unqualified products.

10. Power supply:220V/50HZ

11. Air pressure: Air compressor requirements 0.3-0.8MP

12. Industrial computer, XP operating system, 25 inch touch screen operation