X-ray on-line liquid level detector

Product Description

XYW-600 type liquid level detector is a kind of advanced machine which is researched, developed and manufactured by our company, and reaches the advanced level of domestic and abroad.

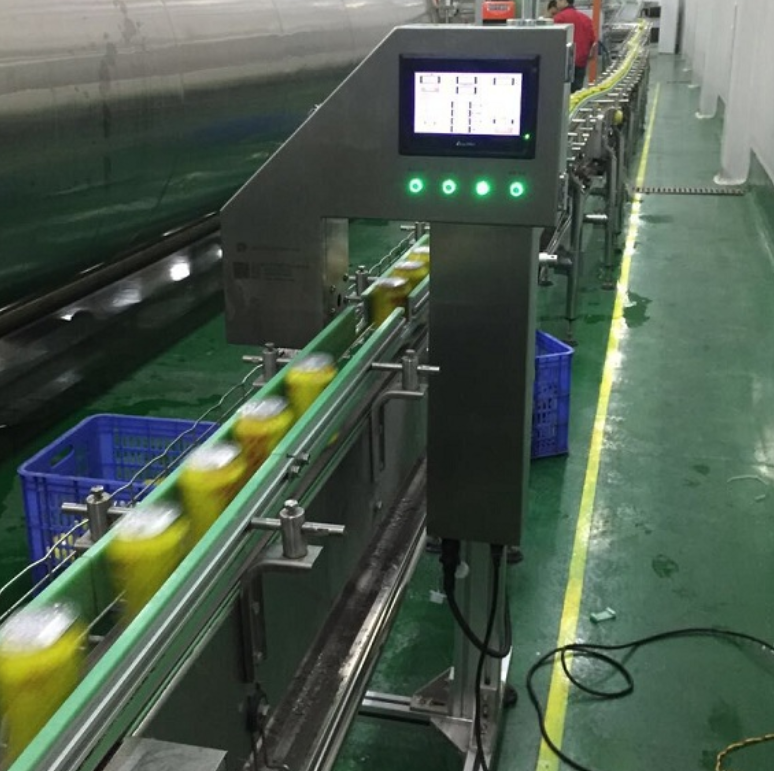

The principle of that “the ray intensity changes with the charge level change of detected material after interaction between low-energy photon source and detected material” is utilized to control and inspect the filling liquid material capacity

Given its non-contact measure way, the product basically solve the problem that the conventional weighing method cannot measure the top space of bottle or can on production line, and it’s widely applied in the automatic online control of filling liquid material production lines (both bottle filling or can filling ) of food, medicine, Chemicals etc.

Functional description

Range of package applied on line detection:

2-Piece aluminum can

3-Piece tin can

PET bottle

Glass bottle

Technical characteristics

(1) There is no need warming-up, the detector can be conducted directly after starting up the production.

(2) Non-contact inspection, fast inspection speed, and high accuracy.

(3) The detection machine can automatically fit different speed of production line and realize dynamics detection.

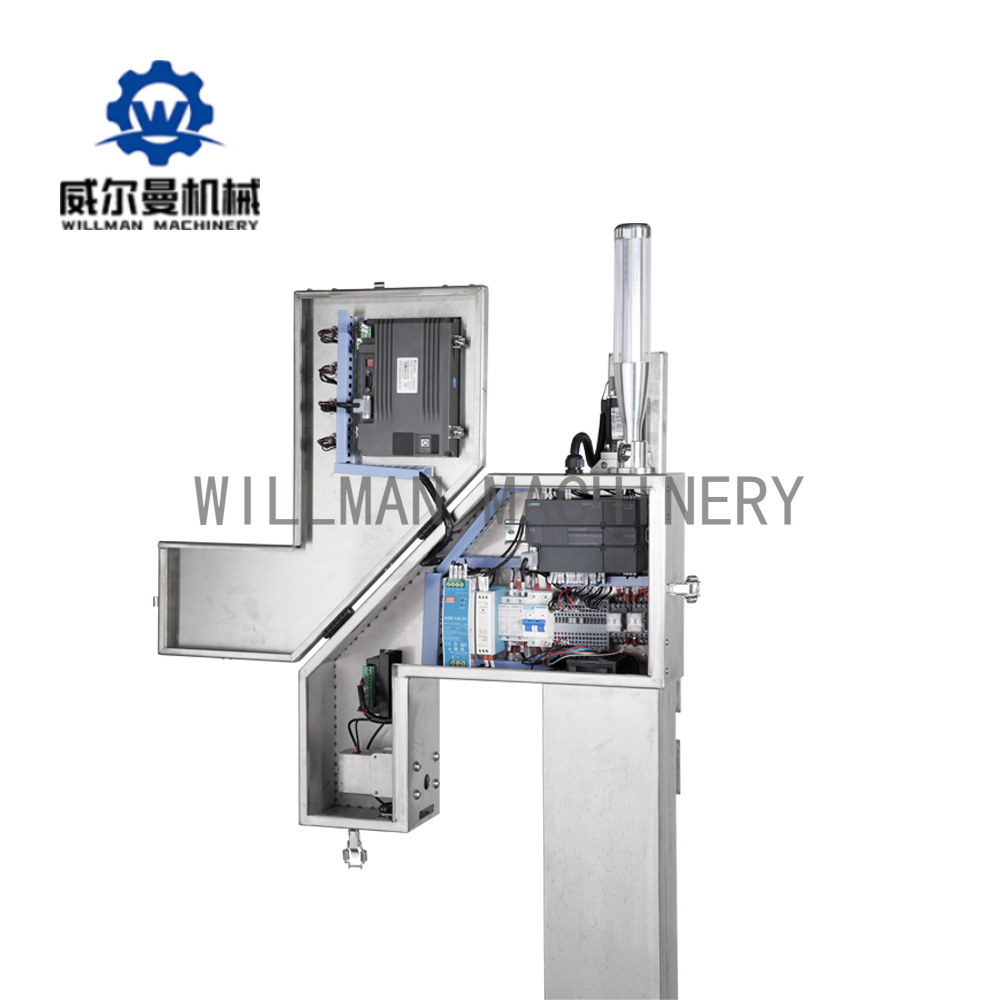

(4) The detection machine is manufactured with stainless steel shell and seal design mainframe, which is anti-fog, anti-water drop and possesses strong environmental suitability.

(5) The radiation of high-frequency ray will be automatically interdicted at free time. (No can no radiation of high-frequency ray )

(6) The product employs hardware circuit implementation and built in operate system, which can ensure long-term stable operation.

(7) Simultaneous alarm of sound and light, automatic remove of unqualified container.

(8) The 9 inch touch screen display provides simple and reliable man-machine operate interface, which is flexible and convenient to change bottle type.

(9) Large screen Chinese display, LED backlit liquid crystal, clear and bright character, man and machine communicate method operation.

(10) Without isotope radioactive source, the product employs soft ray design while its ray protection is safety and reliable.

Major Technical indicators

(1) Band carrier linear speed of production: ≤1.8M/s

(2) Container diameter:20-100mm (Different detectors for different containers concentrations and diameters)

(3)Dynamics container resolution: ±2mm (bubble and shaking may influence the accuracy)

(4)Static liquid level detection accuracy: ≤0.5mm (water)

(5)Static l detection stability of 8 hours: ≤0.15mm (water)

(6)Unqualified container remove ratio: ≥99% (detection speed:1200 can/min)

(7)Temperature range : 0-40 ℃

Detection value ≤0.25mm for 20 ℃ temperature

(8)Working requirements:10ms minimum time width (both with and without can)

(9)Usage environment: 0-40 ℃ temperature, relative humidity ≤ 95%