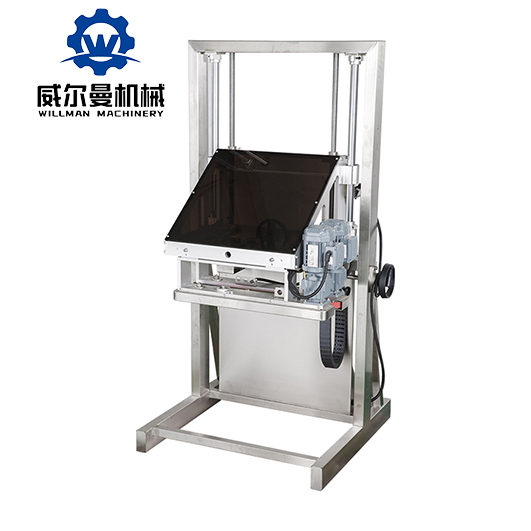

PET Bottles and Containers Leakage detection machine

Product Introduction

It can be used to detect or test internal pressure for soft package like PET bottles or aluminum cans after liquid nitrogen dosing. The device can quickly detect and remove unqualified products and provide sound and light alarm, allowing users to monitor if front-end equipments work properly and aviod unqualified products flowing to market.

When continuous substandard products being kicked out appears, it is a single that there is malfunction happening at the front-end equipment. That is to say, it can be set to find the front-end equipment working status to reduce the loss.

In addition, it is also as as monitor to the detect the volume of liquid nitrogen and adjust if necessary. The device has capability of determining whether the internal pressure is qualified instead of destroying the pakcage.

Technical Parameters

| 1 | Humidity | relative humidity0-100% |

| 2 | Working altitude | 6050 meters above sea level work |

| 3 | Noise | Continuous noise≤78DB(A) |

| 4 | Weight | 150kg |

| 5 | Capability | 0-400 cans/min |

| 6 | Test accuracy | 99.99% |

| 7 | Compressed air | Used to supply the elimination of cylinders. Need 8mm diameter air tube, pressure range of 4-6 kg. |

| 8 | Capability | 0-400 cans/min |

| 9 | Test applicable pressure range | 0-6bar |

| 10 | Static accuracy detection | 0.01bar |