Aluminum Can Filling and Seaming Machine Monoblock

Product Description

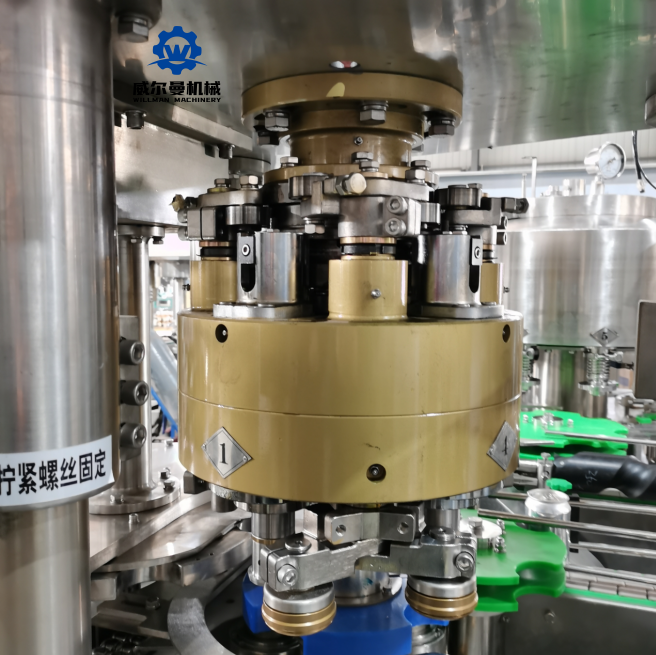

Aluminum Can Filling and Seaming Machine Monoblock

This combined machine unit adopts a single-chamber normal pressure quantitative filling valve for filling, which is a product developed by our factory and obtained a national patent.

The sealing is double seaming spinning forming double seaming structure, frequency conversion speed control, with characteristic of stable filling, precise flow and filling, high speed, accurate filling volume, no cans no filling, no dripping, automatic control of the liquid level in filling tank.

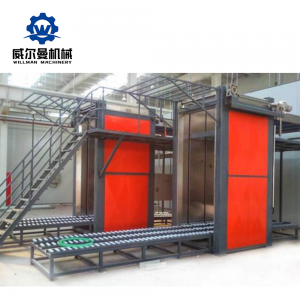

There is CIP connect interface for CIP connect cleaning and disinfection. The production speed is continuously adjustable.

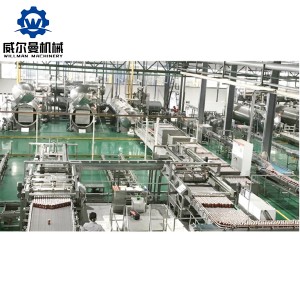

It is suitable for various types of round tin can or aluminum can for filling and sealing.

Changing parts are available for different sizes of can.

Technical Parameters

1. Filling head: 18 heads

2. Seaming head: 4 heads

3.Capacity: 0-250 cpm

4. Range of diameter: 52.5-99mm

5. Range of height: 70-133mm

6. Dimension: 3100 x 1800 x 2200mm

7. Weight: 4000 kg

8. Power: 4.5 kw

Material Introduction

1. Transmission parts:High quality carbon steel

2. Filling Valve Component: SUS304 stainless steel, silicon rubber

3. Filling Tank:SUS304 stainless steel

4. Mixing Stirrer : SUS304 stainless steel

5. Filling parts:Pneumatic Control,SUS304 stainless steel

6. Conveyor belt parts: The guid plate is SUS304 stainless steel, and the conveyor chain is POM flat top chain

7.Workbench parts:The basic frame is made of carbon steel structure with SUS304 stainless steel guard plate outside

8. Sealing Parts:High-quality carbon steel, bearing steel, tool steel