Canned mackerel Fish Production Line Fish Canning Equipment Manufacturer from China

Product Application

As the manufacturer of professional canned food machinery, canned mackerel production line is the one of the experienced projects for us.

It is canned mackerel fish production line, but it can be put in to production for canned sardine.

We design the production line layout for customers according to their requirements. Whole production line solution from fresh or frozen mackerel fish to final canned products packing.

The production line can be high degree automation , it has the advantage of high output, labor saving, stable running ,easy operation

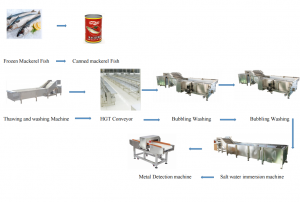

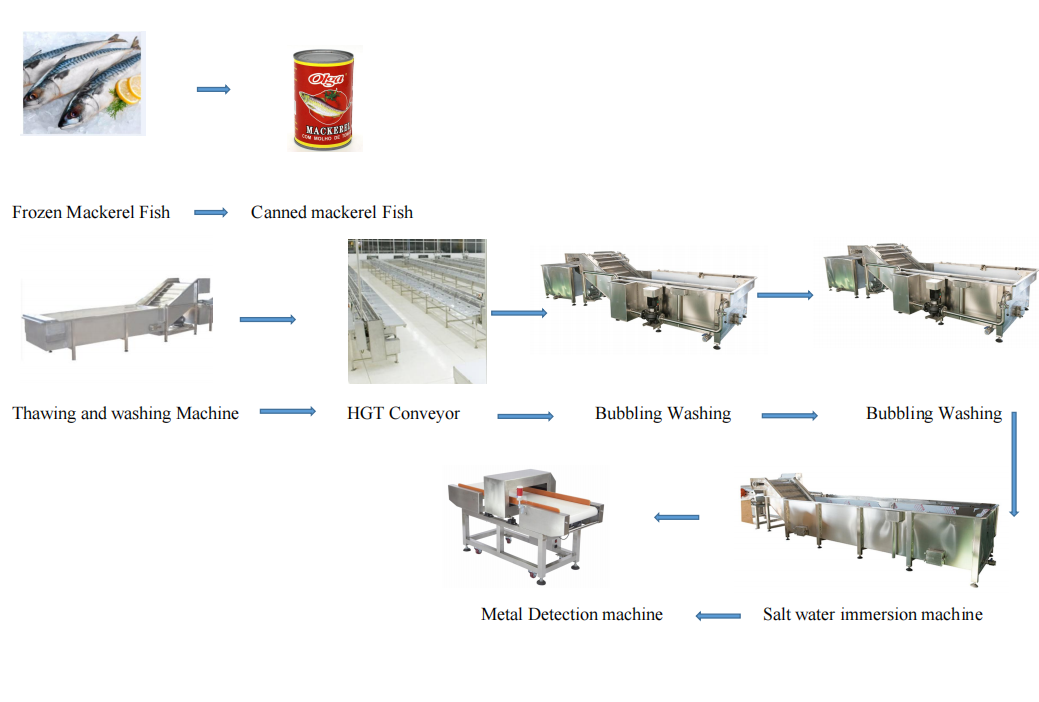

Canned Mackerel Fish Process Flow

Canned mackerel fish production line (Production flow chart)

Canned mackerel deforesting machine

Mackerel HGT (Head / Gut/ Tail) Machine

Bubbling Washing Machine

Salt Water Immersion Machine

Metal Detector

Fish Filling and Weighing Conveyor machine

For Canning Production Line :

Empty Can Depalletizing Machine

Empty Can Washing Machine

Exhaustor ( Exhausting Box Tunnel)

De-watering Machine

Brine /Tomato sauce Filling Machine (Linear type)

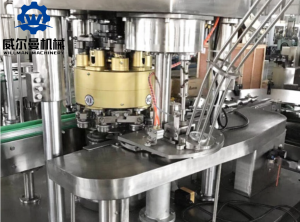

Tin Can Seaming Machine

Sealed Can Washing Machine

Basket Loading and unloading Machine (Semi-auto)

Retort Pot (Sterilization machine)

Drying machine

Labeling machine

Coding machine

Carton Packing Machine

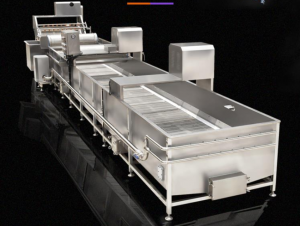

Canned Mackerel Pre-production Process

Canned Mackerel Canning Production Line

Technical Parameter Details for Main Machine in Canned Mackerel Production Line

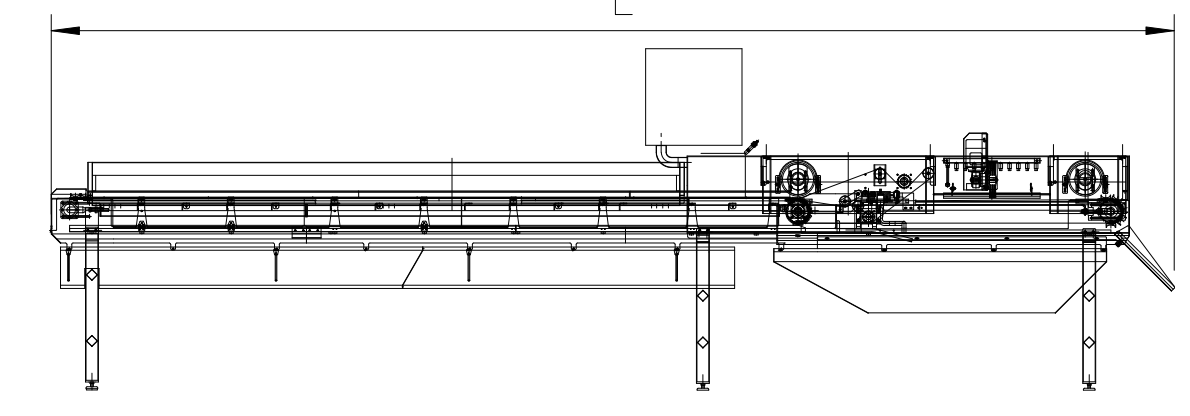

1. Thawing and Washing machine

- Main Material : SUS304 stainless steel

- The conveying adopts stainless steel punched plate chain, with bubbling and surfing

- The bracket adopts 40x80x2mm square tube, and the thickness of the tank is 2.5mm

- Power 4.8 kw, stepless speed regulation

- Dimension : 7000×1200×1200 mm

Mackerel or sardine Fish Grading Machine

This nobbing machine is designed for the cutting of sardines, mackerel or sprat and other species of small fish.

The fish are fed manually on slot-like conveyor, and the feeding speed depends on the number of wrokers. The fish can be cut in different ways , e.g. cut off head, cut off head and tail, or cut off head and tail and gutting and cutting into pieces.

Machine consists of fish collecting platform and slot-like conveyor and nobbing head. The slot-like conveyor is designed to ensure correct placing of fish prior to head-cutting. The operators feed the fish and control feeding of the pocket conveyor manually, ensuring correct feeding and avoiding build-up of damaged fish. The nobbing head cuts the head off the fish exactly at the required point by means of a rotating knife. After exact placnig of cutting off head, another device on nobbing head sucks out fish viscera, which are discharged by the vacuum system.

Mackerel or sardine Fish Nobbing Machine (HGT Machine )

This nobbing machine is designed for the cutting of sardines, mackerel or sprat and other species of small fish.

The fish are fed manually on slot-like conveyor, and the feeding speed depends on the number of wrokers. The fish can be cut in different ways , e.g. cut off head, cut off head and tail, or cut off head and tail and gutting and cutting into pieces.

Machine consists of fish collecting platform and slot-like conveyor and nobbing head. The slot-like conveyor is designed to ensure correct placing of fish prior to head-cutting. The operators feed the fish and control feeding of the pocket conveyor manually, ensuring correct feeding and avoiding build-up of damaged fish. The nobbing head cuts the head off the fish exactly at the required point by means of a rotating knife. After exact placnig of cutting off head, another device on nobbing head sucks out fish viscera, which are discharged by the vacuum system.